ASTM D2063 Compliant • Class 0.5 Accuracy • Factory Direct

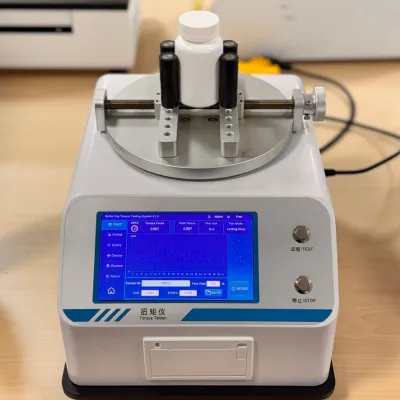

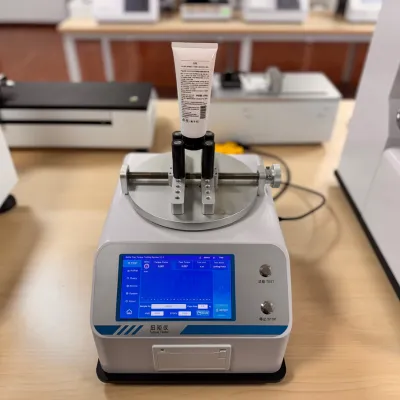

Master your capping quality with lab-grade precision. The NLY-20A features a 7-inch HD Touch Screen, Dual-Mode Testing (Opening/Locking), and built-in data printing. Complies with ASTM, ISO, and ChP standards for Pharmaceutical and Beverage packaging.

7-inch HD Touch Screen with real-time curves

Measures both Removal (Opening) & Application (Locking) Torque

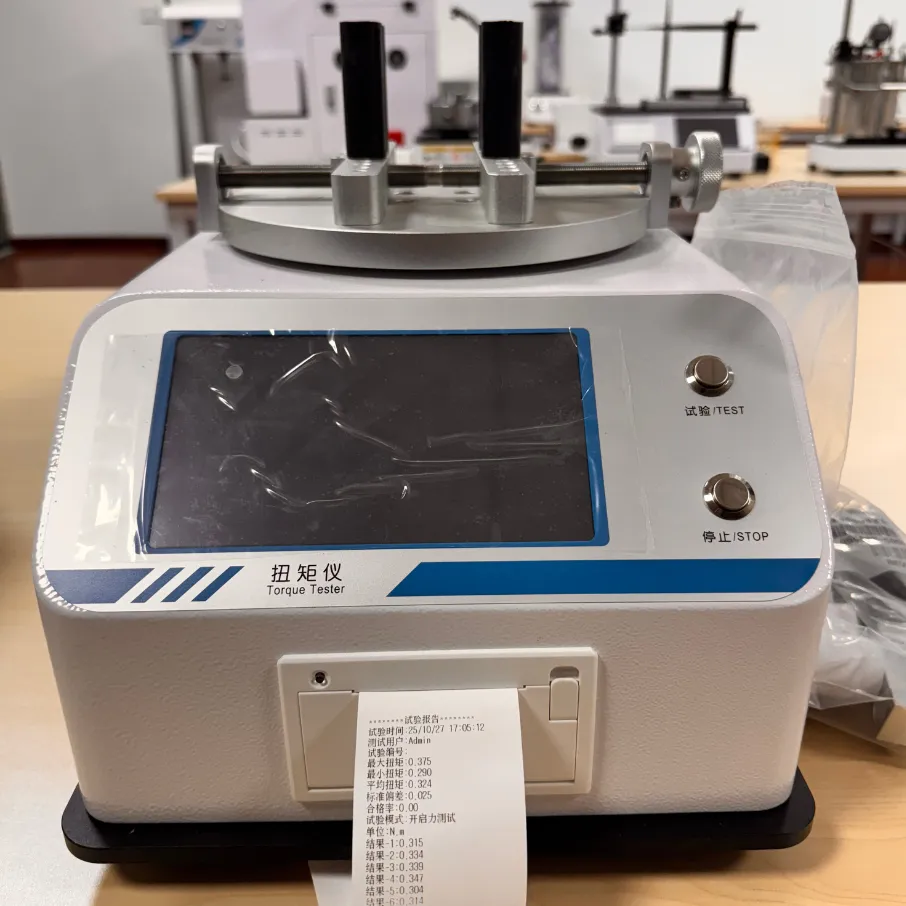

Built-in Micro-printer & USB Data Export

Class 0.5 Accuracy with 0.001 N.m Resolution

Lab-Grade Precision

Stop guessing your capping quality. The NLY-20A uses a high-frequency sampling chip to capture the precise moment of seal release or lock.

Four core advantages that help you standardize capping quality, reduce leakage risk, and generate audit-ready records.

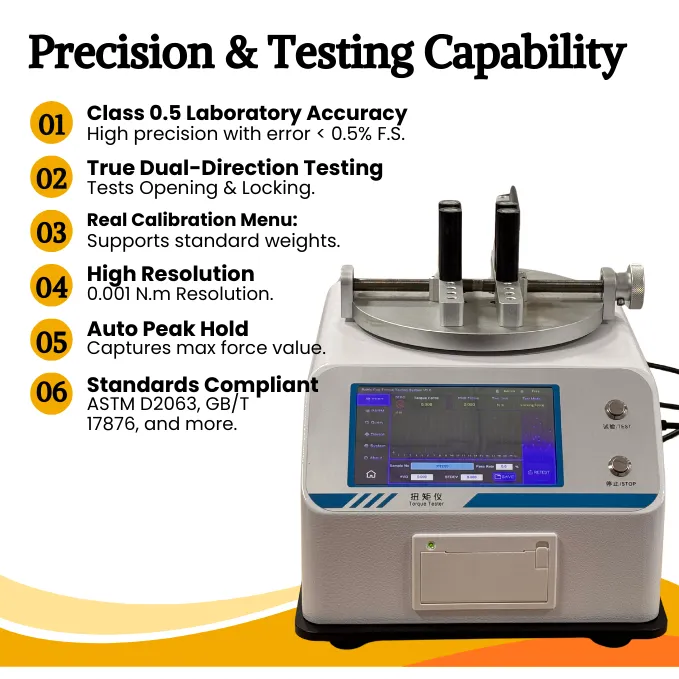

Class 0.5 laboratory accuracy (<0.5% F.S.), true dual-direction testing (Opening & Locking), 0.001 N·m resolution, auto peak hold, calibration menu support, and ASTM/GB compliant performance.

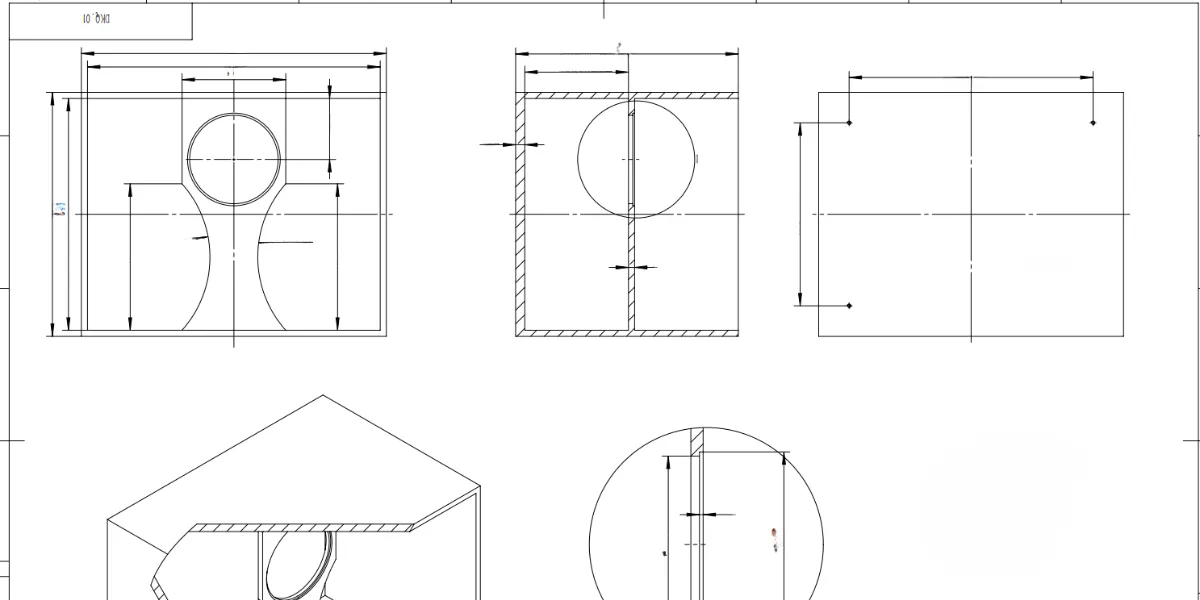

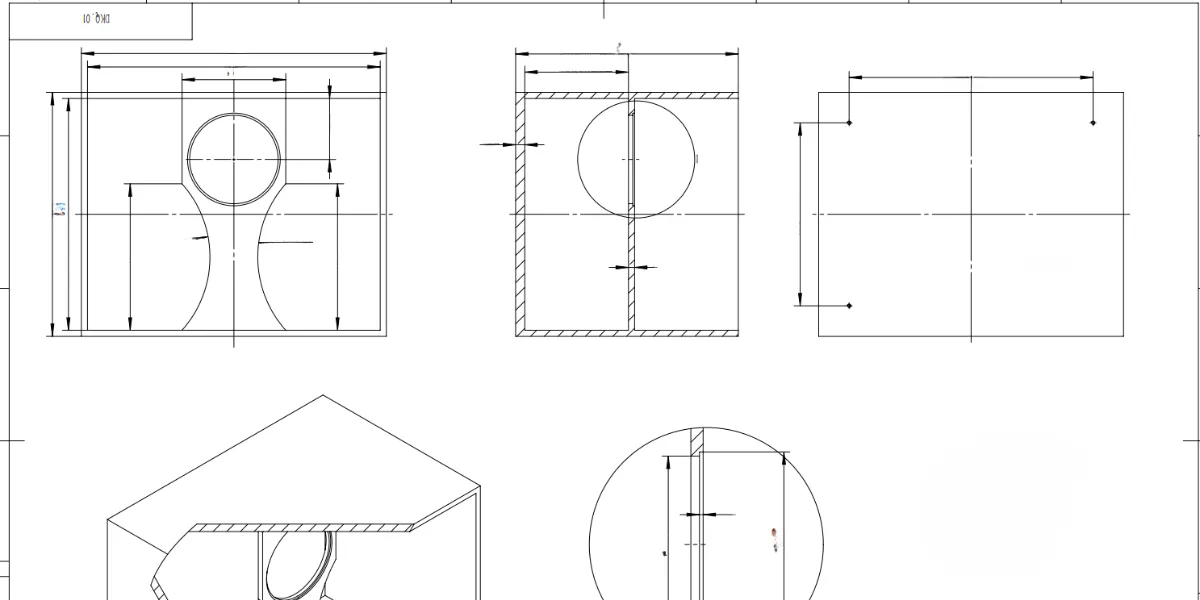

4-post anti-slip grip secures round/square/flat containers. Wide clamping range (Φ5–180 mm), non-destructive holding, overload protection, rugged metal housing—and rapid customization for non-standard shapes.

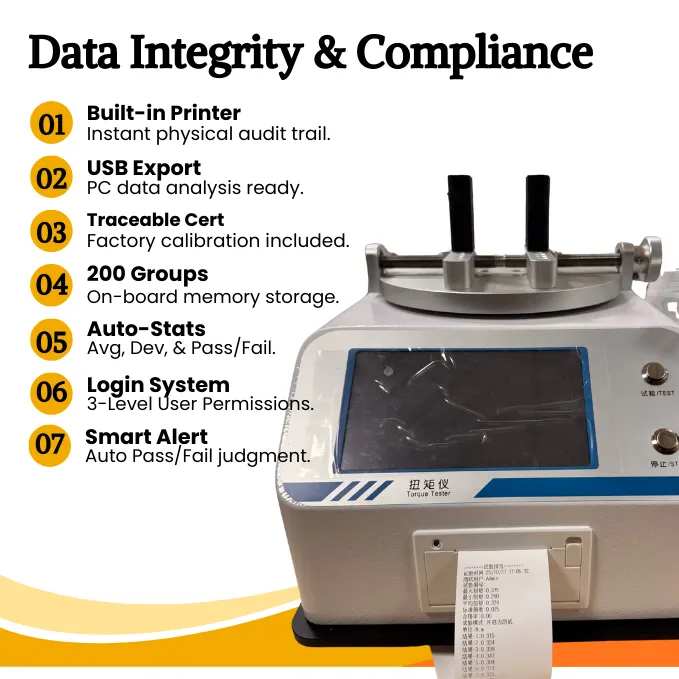

Built-in printer for instant audit trail, USB export for analysis, traceable calibration certificate, 200-group memory, auto statistics (Avg/Dev/Pass-Fail), 3-level user permissions, and smart alerts.

7" HD touch screen with live curve display, 4 selectable units (N·m, kg·cm, lb·in, N·cm), strip analysis for thread failure, 72-hour aging test, factory-direct support, and dual-language UI.

Versatile Solutions

From safeguarding pharmaceutical sterility to ensuring consumer accessibility in beverages, the NLY-20A delivers compliant torque analysis.

Critical for carbonated drinks and aseptic lines. The NLY-20A balances 'Seal Integrity' (preventing CO2 leakage) with 'Consumer Accessibility' (Removal Torque). Complies with GB/T 17876 and ASTM D2063.

Essential for Container Closure Integrity (CCI). Validates torque on Child-Resistant Caps (CRC) and eye-drop bottles to prevent moisture ingress. Features data integrity compliance required by ChP 2025 and GMP.

Solves the challenge of gripping soft packaging. Our specialized 4-Post Clamping System secures hand cream tubes and lotion pumps without deformation, while detecting thread failure in premium jars.

Heavy-duty testing capability up to 40 Nm. Ideal for measuring the locking force of vacuum flasks (thermos cups), insulation pots, and industrial nut/bolt assemblies.

Proven Results

Discover how industry leaders use the NLY-20A to solve critical packaging challenges.

Faced with a 3% leakage rate during transport. By implementing the NLY-20A to monitor 'Locking Force', leakage complaints dropped by 90%.

Struggling to meet strict Data Integrity requirements for Child-Resistant Caps (CRC). They switched to the NLY-20A for its Built-in Printer and User Login features, successfully passing the audit.

Customers complained premium cream jars were 'impossible to open.' Using the NLY-20A's 'Opening Force' mode, they established a perfect torque window (1.2 - 1.5 N.m).

Product Models

The NLY-20A is a modular platform. Choose the sensor range and software package that fits your testing requirements.

Upgrade Your Lab

See how our digital touch-screen technology outperforms traditional analog torque meters.

| Feature | KHT NLY-20A (Digital) | Traditional Analog Meter | Hand Testing |

|---|---|---|---|

| Precision | ✅ Class 0.5 (0.5% Accuracy) | ⚠️ Class 3-5 (3-5% Error) | ❌ Guesswork |

| Peak Capture | ✅ Auto-Peak Hold (Digital) | ⚠️ Visual Estimation (Hard to catch) | ❌ None |

| Data Records | ✅ Built-in Printer & Storage | ❌ Manual Handwriting | ❌ None |

| Clamping | ✅ 4-Post (Secure & Versatile) | ⚠️ 3-Jaw (Slips easily) | ⚠️ Hand Grip |

| Operation | ✅ 7" Touch Screen | ⚠️ Mechanical Dial | ❌ Manual |

Factory Direct

From raw materials to the final instrument, every step happens in our Jinan facility. We control the quality chain.

Our dedicated R&D team holds independent intellectual property rights, focusing on packaging detection theory.

Every NLY-20A undergoes a rigorous multi-point calibration process using certified standard weights to guarantee Class 0.5 precision.

Our 4-post clamping mechanisms are machined via high-precision CNC centers ensuring perfect concentricity.

All sensors and motherboards undergo a continuous 72-hour aging test to eliminate early-stage failures.

We perform comprehensive functional checks on every feature—from the touch screen sensitivity to the printer output.

Instruments are encased in custom-molded foam and reinforced wooden crates for safe international shipping.

Why Choose Us

As a source manufacturer with independent IP, we control the entire lifecycle from R&D to final assembly.

Our in-house engineering team holds core patents and algorithms.

ISO-certified assembly lines with strict SOPs ensure consistent build quality.

Every unit undergoes multi-point calibration using standard weights.

With 50+ units in ready stock, we guarantee dispatch within 24-48 hours.

Reliability

Proven performance in the global packaging industry.

Real Feedback

Hear from Quality Managers who rely on the NLY-20A.

Plant QA Manager | Regional Bottling Group

Lab Director | Pharma Solutions Inc.

Production Engineer | Specialty Oils Ltd.

Act Now

Get the factory-direct precision you need. Contact us for a quote and technical consultation.

© 2025 KHT NLY-20A Torque Tester | All rights reserved.